Manual vs automatic – Manual vs. automatic sets the stage for a detailed exploration of contrasting approaches in various fields. This guide delves into the core differences, advantages, disadvantages, and practical applications of both manual and automatic systems. From manufacturing to healthcare, the implications of choosing one method over another are significant.

The comparison spans industries, examining the historical context, cost analysis, workforce impact, and safety considerations. A deeper understanding of these contrasting approaches is essential for informed decision-making in a rapidly evolving technological landscape.

Introduction to Manual vs. Automatic Systems

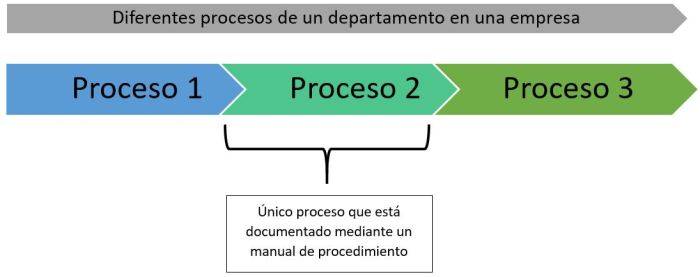

Manual and automatic systems represent distinct approaches to accomplishing tasks. Manual systems rely on human intervention and control, while automatic systems operate independently, often with minimal or no human oversight. This fundamental difference shapes their characteristics, applications, and historical trajectories. Understanding these contrasts is crucial in evaluating the effectiveness and suitability of different methods in various domains.

Defining Manual and Automatic Systems

Manual systems are processes where human effort and decision-making are directly involved in every stage. Examples range from manually assembling a product to conducting a survey by hand. Conversely, automatic systems are those that operate independently with pre-programmed instructions, carrying out tasks without continuous human interaction. Automated systems are increasingly common in industrial settings, from automated manufacturing lines to robotic surgery.

Fundamental Differences

The core distinction lies in the level of human involvement. Manual systems require constant human input and decision-making, while automatic systems operate based on pre-defined instructions. This difference impacts efficiency, accuracy, and adaptability. Manual systems can be more flexible, adaptable to changing circumstances, but typically slower and more prone to human error. Automatic systems are often faster and more consistent, but less adaptable to unexpected situations.

The choice between manual and automatic systems depends on the specific requirements of the task, considering factors like desired speed, accuracy, and cost.

Historical Context

The evolution of manual and automatic systems mirrors the progression of technological advancements. Early human civilizations relied heavily on manual labor, with tasks like farming, construction, and transportation performed manually. As technology advanced, automation gradually emerged, initially in simple mechanical forms like water wheels and windmills. This trend continued with the Industrial Revolution, where automation significantly increased productivity in manufacturing.

In the modern era, automation has expanded into various sectors, from healthcare to finance, reflecting ongoing technological advancements and changing societal needs. The adoption of automation has consistently driven efficiency gains across many fields.

Comparison of Key Characteristics

| Characteristic | Manual Systems | Automatic Systems |

|---|---|---|

| Human Involvement | Direct and continuous | Minimal or absent |

| Speed | Generally slower | Generally faster |

| Accuracy | Prone to human error | Potentially higher accuracy |

| Adaptability | More adaptable to changing conditions | Less adaptable to unexpected situations |

| Cost | Potentially lower initial cost | Potentially higher initial cost, but lower long-term cost |

| Examples | Manual data entry, hand-painting, assembling a product | Automated manufacturing lines, robotic surgery, self-driving cars |

Applications in Different Industries

Manual and automatic systems are integral components in diverse industries, each offering unique advantages and disadvantages. Understanding their applications in specific sectors is crucial for evaluating their efficiency and cost-effectiveness. This section delves into the prevalence of manual and automatic systems across various industries, highlighting their strengths and weaknesses in different contexts.Industries often adopt systems best suited to their specific needs and the nature of their work.

A deep understanding of these needs, combined with careful analysis of operational costs, helps companies determine the optimal approach for achieving desired outputs.

Industries Favoring Manual Systems

Manual systems remain prevalent in industries where tasks are highly customized, require intricate craftsmanship, or involve unpredictable variables. For example, artisanal crafts, like bespoke tailoring or high-end jewelry making, heavily rely on manual dexterity and artistic judgment. Similarly, certain repair and maintenance tasks, especially in niche equipment or machinery, often demand specialized manual expertise that automatic systems can’t replicate.

Industries Dominated by Automatic Systems

High-volume manufacturing, assembly lines, and industries with standardized processes frequently employ automatic systems for their efficiency and consistency. Industries such as automotive manufacturing, electronics production, and certain food processing sectors extensively utilize automated equipment to handle repetitive tasks. The predictable nature of these processes allows automation to maximize output and minimize human error.

Choosing between a manual and automatic transmission often comes down to personal preference, but fuel efficiency can also play a role. For example, drivers seeking the best possible fuel economy should research fuel efficient cars , as some models are optimized for higher MPG regardless of transmission type. Ultimately, the decision boils down to balancing cost, comfort, and driving style when comparing manual vs automatic.

Efficiency and Cost-Effectiveness in Manufacturing

Comparing manual and automatic systems in manufacturing reveals distinct differences in efficiency and cost-effectiveness. Manual systems, while often adaptable to unique situations, typically lag in terms of output compared to automated counterparts. Automated systems can dramatically increase production rates, reduce labor costs in the long run, and enhance product consistency. However, the initial investment in automated equipment can be substantial.

The choice between manual and automatic systems often depends on the volume of production, the complexity of the product, and the available budget.

Automation in Service Sectors

Automation is progressively impacting various service sectors. Examples include automated customer service systems, online ordering platforms, and robotic process automation (RPA) for tasks like data entry and report generation. While these automated systems can streamline operations and reduce wait times, the human element remains vital for complex customer interactions and tasks requiring empathy and nuanced understanding.

Manual and Automatic Systems in Healthcare

In healthcare, both manual and automatic systems play crucial roles. Manual systems, such as surgical instruments and examination tools, remain essential for intricate procedures and patient interaction. Automated systems, including robotic surgery, diagnostic imaging, and automated medication dispensing systems, are increasingly employed for efficiency and precision. The integration of these systems aims to improve patient outcomes and streamline healthcare processes.

Comparison Across Industries

| Industry | Manual Systems | Automatic Systems |

|---|---|---|

| Artisanal Crafts | Prevalent; specialized skills required | Limited use; impractical for unique designs |

| High-Volume Manufacturing | Less common; high labor costs | Prevalent; high production rates |

| Food Processing (certain areas) | Prevalent in some areas; tasks may require dexterity | Prevalent in large-scale operations; high throughput |

| Healthcare | Essential for complex procedures; patient interaction | Improving patient outcomes; streamlining processes |

| Customer Service | Direct human interaction | Automated responses; reduced wait times |

Advantages and Disadvantages of Manual Systems

Manual systems, relying on human intervention, continue to play a crucial role in various industries, particularly in situations where automation is not feasible or cost-effective. Their adaptability and flexibility often outweigh the limitations presented by their inherent inefficiencies.While automation offers significant improvements in speed and accuracy, manual systems can be surprisingly effective in specific contexts. Understanding the nuances of both their strengths and weaknesses is key to selecting the most appropriate approach for a given task.

Advantages of Manual Systems

Manual systems offer a degree of flexibility and adaptability that often surpasses automated alternatives. Their responsiveness to unique situations and the ability to handle complex, non-standard tasks are significant benefits. Human operators can readily adjust to changing circumstances and make real-time decisions, which can be crucial in unpredictable environments. This adaptability is especially valuable in situations requiring a high degree of judgment and discretion, such as complex diagnoses in medicine or intricate repairs in specialized manufacturing.

Disadvantages of Manual Systems in Terms of Efficiency and Cost

Manual systems often suffer from significant limitations in terms of efficiency and cost. Human error, inconsistent performance, and the potential for delays are common issues. The time required for each task can vary significantly based on operator skill and motivation, leading to inconsistent output. These variations in speed and quality necessitate greater oversight and quality control measures, further increasing operational costs.

Moreover, the lack of automation can lead to bottlenecks in production and a reduction in overall output compared to automated systems.

Examples of Situations Where Manual Systems Are Preferred

Manual systems remain preferable in certain scenarios. For instance, in industries like art restoration or fine jewelry creation, the intricate nature of the work often necessitates the precision and dexterity of human hands. Similarly, in environments with low production volumes or highly specialized tasks, the flexibility and adaptability of manual systems may outweigh the efficiency gains of automation.

Another example would be situations where real-time adjustments are crucial, like in surgical procedures or emergency response operations.

Potential Human Error Factors in Manual Processes

Human error is a significant concern in manual systems. These errors can stem from various sources, including fatigue, distractions, miscommunication, and lack of training. Inaccurate measurements, incorrect data entry, and flawed judgments are further potential pitfalls. The possibility of overlooking critical details or misinterpreting information can have substantial consequences.

- Fatigue: Prolonged periods of work without adequate rest can significantly reduce alertness and accuracy. This is a factor to consider in manual processes requiring sustained effort.

- Distraction: External factors, including interruptions and environmental noise, can lead to errors and decreased performance.

- Miscommunication: Poor communication between team members or inadequate instructions can result in errors.

- Lack of training: Inadequate training can result in operators not fully understanding the procedures, potentially leading to mistakes.

- Inadequate equipment: Using worn-out or malfunctioning equipment can also lead to errors in manual processes.

Role of Human Intervention in Manual Systems

Human intervention is central to the operation of manual systems. Operators are responsible for executing tasks, monitoring processes, making decisions, and adapting to changing conditions. The degree of human involvement varies depending on the complexity of the system.

Contrasting Pros and Cons of Manual Systems

| Feature | Pros | Cons |

|---|---|---|

| Flexibility | Adaptable to unique situations and non-standard tasks. | Inconsistent performance due to human variability. |

| Cost | Potentially lower initial investment compared to automation. | Higher ongoing costs due to labor and potential errors. |

| Efficiency | Suitable for small-scale production or highly specialized tasks. | Lower output compared to automation in high-volume environments. |

| Error Rate | — | High potential for human error. |

| Adaptability | Reacts to changes in real-time. | Requires constant supervision and monitoring. |

Advantages and Disadvantages of Automatic Systems

Automatic systems, encompassing everything from robotic assembly lines to sophisticated software algorithms, are increasingly prevalent across diverse industries. Their adoption brings significant advantages, but also presents challenges that need careful consideration. Understanding both sides of the coin is crucial for effective implementation and successful integration into existing workflows.

Benefits of Automatic Systems

Automatic systems offer a multitude of benefits, primarily revolving around enhanced efficiency and productivity. Reduced human error is a significant advantage, leading to higher quality outputs and lower defect rates. This, in turn, can translate into cost savings and increased profitability. Furthermore, automatic systems can operate continuously, 24/7, maximizing output and production capacity, especially in industries with high-volume demands.

Automated processes can also handle tasks that are physically demanding, hazardous, or repetitive for humans, minimizing worker strain and improving workplace safety.

Drawbacks of Automatic Systems

While automatic systems boast numerous benefits, their implementation is not without drawbacks. One significant concern is the substantial upfront investment required for purchasing and installing automated equipment. The cost of hardware, software, and integration can be substantial, especially for large-scale installations. This high initial cost can pose a significant barrier to entry for smaller businesses or organizations with limited capital resources.

Furthermore, maintaining and repairing automatic systems can be complex and costly. Specialized technicians and equipment might be necessary, leading to higher ongoing operational expenses.

Situations Where Automatic Systems Excel

Automatic systems often outperform manual systems in situations demanding high precision, speed, or volume. For instance, in high-volume manufacturing, automated assembly lines can significantly increase production output compared to manual labor. Similarly, in environments with hazardous or repetitive tasks, automation can drastically reduce risks and improve worker safety. Complex calculations and data analysis tasks, such as those in financial modeling or scientific research, are also frequently better handled by automatic systems.

The consistent performance and precision of automated systems are often crucial for maintaining product quality and consistency.

Maintenance Requirements for Automatic Systems

Regular maintenance is crucial for ensuring the optimal performance and longevity of automatic systems. Preventive maintenance schedules are often necessary to detect and address potential issues before they escalate into major breakdowns. This proactive approach can minimize downtime and maximize operational efficiency. Sophisticated automatic systems may require specialized technicians with specific knowledge of the system’s intricacies. The complexity of the maintenance process can significantly impact the overall cost of ownership.

Potential Risks and Safety Concerns

Automation, while beneficial, also presents potential risks and safety concerns. The integration of automatic systems can displace human workers in certain roles, potentially leading to job losses or requiring workforce retraining. Safety protocols and safeguards are essential to mitigate the risks associated with machinery and automated processes. The potential for system failures or malfunctions must be considered, requiring redundant systems or safety mechanisms to prevent accidents or mitigate their impact.

Comparison Table: Manual vs. Automatic Systems, Manual vs automatic

| Feature | Manual Systems | Automatic Systems |

|---|---|---|

| Initial Cost | Relatively low | Relatively high |

| Operational Cost | Potentially high due to labor costs | Potentially high due to maintenance and energy costs |

| Speed | Variable, often slower | High speed and efficiency |

| Precision | Prone to human error | High precision and consistency |

| Scalability | Limited | Potentially high |

| Safety | Potentially higher risk in hazardous environments | Can be safer, but requires safety protocols |

| Flexibility | Highly flexible | Less flexible for specific tasks |

Cost Analysis and Return on Investment (ROI)

Assessing the financial viability of a system, whether manual or automatic, is crucial. A thorough cost analysis, encompassing both initial investment and long-term operational expenses, is vital for making informed decisions. Understanding the potential return on investment (ROI) provides a clear picture of the financial benefits and justifies the selection of a particular approach.

Initial Investment Costs

The initial investment costs for manual systems typically involve minimal upfront expenses, mainly focusing on labor and basic tools. Automatic systems, conversely, demand substantial initial capital for equipment acquisition, installation, and potentially, software licenses. This disparity in upfront costs is a significant factor in evaluating the overall financial implications of each system. Factors influencing initial investment costs include the complexity of the system, the required level of automation, and the specific technologies employed.

Long-Term Operational Costs

Beyond initial investment, long-term operational costs play a pivotal role in determining the true cost of each system. Manual systems often involve recurring costs like labor wages, training, and maintenance of tools and equipment. In contrast, automatic systems may require specialized maintenance personnel, regular software updates, and potential energy consumption. The operational costs of an automatic system can be substantial but may lead to reduced labor expenses and improved efficiency in the long run.

Calculating ROI for Automation Projects

A crucial step in evaluating the financial viability of automation projects is calculating the ROI. This involves determining the net present value of future savings against the initial investment. A common formula used to calculate ROI is:

(Total Savings – Initial Investment) / Initial Investment – 100%

For instance, if a company invests $100,000 in an automatic system and expects to save $20,000 annually, the ROI can be calculated as follows:

(20,000

- 5 years – 100,000) / 100,000

- 100% = 0%

(Assuming a 5-year payback period). This calculation demonstrates the necessity to consider both short-term and long-term gains to ensure a positive ROI.

Successful ROI Cases for Automatic Systems

Numerous examples illustrate the positive ROI associated with automatic systems. A manufacturing company transitioning from manual assembly to robotic automation saw a substantial increase in output and a decrease in labor costs. The increased efficiency and reduced errors led to significant cost savings over time.

Factors Affecting Payback Period for Automatic Systems

Several factors can influence the payback period for automatic systems, including the initial investment cost, the size of the projected savings, and the rate of return on investment. A complex and costly automation system may have a longer payback period than a simpler system. Furthermore, the projected savings must be substantial to compensate for the initial investment cost.

The rate of return on investment is also a crucial factor in determining the payback period. For example, a system with a higher rate of return might recoup the investment sooner.

Cost Breakdown for Different Systems

| System Type | Initial Investment | Annual Operational Costs | Total Estimated Cost (5 years) |

|---|---|---|---|

| Manual System (e.g., Assembly Line) | $5,000 | $10,000 | $65,000 |

| Automatic System (e.g., Robotic Arm) | $50,000 | $5,000 | $80,000 |

This table provides a simplified illustration of the cost breakdown for various systems. Actual costs may vary based on specific factors and the nature of the automation process. A more detailed analysis is essential for accurate estimations.

Impact on Workforce and Skills: Manual Vs Automatic

Automation’s impact on the workforce is multifaceted, presenting both challenges and opportunities. While some jobs may be displaced, new roles and skill requirements emerge. Understanding this dynamic is crucial for effective workforce adaptation and maximizing the benefits of automation.The transition to automated systems necessitates a shift in the skills profile of the workforce. Traditional manual tasks are increasingly being automated, requiring workers to adapt to new technologies and methodologies.

This necessitates reskilling and upskilling initiatives to equip employees with the competencies needed for the evolving job market.

Potential Impact on Employment

The introduction of automated systems can lead to job displacement in sectors where tasks are readily automatable. For example, repetitive manufacturing processes are often replaced by robots, impacting the workforce previously dedicated to these tasks. However, automation also creates new jobs in areas such as system design, maintenance, and programming. The net impact on employment depends on the speed of adaptation and the ability of workers to acquire new skills.

Required Skill Sets for Operating Automatic Systems

Operating and maintaining automatic systems demands a unique skill set. Workers need a combination of technical proficiency and problem-solving abilities. This includes programming, data analysis, troubleshooting, and understanding the underlying principles of automation technologies. Examples of specific skills include proficiency in industrial automation software, robotics programming languages, and machine learning algorithms.

Reskilling and Upskilling Needs

To effectively navigate the transition to automation, substantial reskilling and upskilling initiatives are vital. These programs should equip workers with the technical competencies demanded by automated systems. Educational institutions and companies must collaborate to develop relevant training programs that address the emerging skill gaps. This includes providing courses on programming, data analysis, robotics, and related fields.

Challenges in Workforce Adaptation

Several challenges hinder the smooth adaptation of the workforce to automation. The pace of technological advancement can outstrip the capacity for training and reskilling, leading to skills gaps. The cost of training programs and the willingness of individuals to invest in reskilling can also be significant barriers. Furthermore, the complexity of some automation systems can pose challenges for workers accustomed to simpler tasks.

Creation of New Jobs Related to Automation

Automation necessitates a new generation of skilled professionals. These include automation engineers, data scientists, robotics technicians, and maintenance specialists. The demand for these roles is growing, creating opportunities for workers willing to adapt and acquire new skills.

Summary Table: Impact of Automation on the Workforce

| Aspect | Impact |

|---|---|

| Job Displacement | Certain roles, particularly those involving repetitive tasks, may be replaced by automation. |

| Job Creation | New roles focused on automation, maintenance, and data analysis emerge. |

| Skill Requirements | Workers need enhanced technical skills in areas like programming, data analysis, and maintenance. |

| Reskilling/Upskilling | Significant investment in training programs is needed to adapt the workforce. |

| Workforce Adaptation Challenges | Pace of technological advancement, cost of training, and complexity of systems pose challenges. |

Safety and Reliability Considerations

Manual and automatic systems, while offering distinct advantages, present varying safety and reliability profiles. Understanding these nuances is crucial for implementing systems that minimize risks and maximize operational efficiency. Careful consideration of potential hazards and the establishment of robust safety protocols are essential to ensure the well-being of personnel and the integrity of the equipment.Careful evaluation of both manual and automated processes allows for a proactive approach to safety and reliability.

This involves identifying potential risks, implementing preventive measures, and developing contingency plans. The goal is to create a system that is not only efficient but also secure and reliable.

Potential Safety Hazards of Manual Systems

Manual systems, while often simpler in design, can introduce various safety hazards. Human error, fatigue, and inadequate training are common contributors to accidents. For instance, repetitive tasks can lead to musculoskeletal disorders, while a lack of proper safety equipment can result in injuries from physical hazards. Improper handling of materials or tools, along with a lack of clear safety protocols, can significantly increase the risk of accidents in manual operations.

Potential Safety Hazards of Automatic Systems

Automatic systems, while generally safer than manual systems due to their reduced human interaction, have unique potential safety hazards. Malfunctions in the automated system, such as equipment failures, software glitches, or sensor inaccuracies, can create hazardous situations. Additionally, unexpected events or external factors can disrupt the automated process, potentially causing harm to personnel or damage to property. The complexity of some automatic systems can also make troubleshooting and maintenance more challenging, increasing the risk of accidents during maintenance or repairs.

Reliability Comparison

Manual systems rely heavily on human factors, which can introduce inconsistencies and variability in performance. This can lead to variations in output quality and potential errors in the process. Automatic systems, conversely, offer higher reliability when functioning as designed. However, breakdowns in the automated system, such as sensor failures, can lead to unexpected downtime and interruptions in the production process.

Maintaining high reliability requires rigorous testing, maintenance, and backup systems to mitigate these risks.

Safety Protocols for Automatic Systems

Implementing robust safety protocols is critical for operating automatic systems safely. This includes regular maintenance checks, software updates, and operator training on safety procedures. Redundancy in critical components and emergency shut-off mechanisms are crucial for preventing accidents. Moreover, clear emergency response plans should be developed and regularly reviewed. A robust safety culture that emphasizes vigilance and adherence to safety protocols is essential for ensuring the safety of personnel and the integrity of the equipment.

Mitigating Risks in Manual and Automatic Processes

Mitigating risks in both manual and automatic processes requires a multi-faceted approach. For manual systems, proper training, clear safety procedures, and adequate personal protective equipment (PPE) are essential. For automatic systems, regular maintenance, comprehensive testing, and the implementation of safety interlocks and emergency shutdown systems are crucial. Moreover, continuous monitoring and evaluation of the systems are vital to identify and address potential issues proactively.

Quality Control in Manual and Automatic Operations

Quality control is essential in both manual and automatic systems. In manual systems, regular inspection and quality checks by trained personnel are necessary. In automatic systems, incorporating quality checks into the automated process, such as sensor-based feedback loops and automated inspection systems, is often more efficient and accurate. Implementing robust quality control measures ensures the consistent production of high-quality outputs and minimizes errors.

Safety Precautions Table

| System Type | Safety Precautions |

|---|---|

| Manual |

|

| Automatic |

|

Technological Advancements and Trends

Technological advancements are rapidly transforming the landscape of manual and automatic systems. This evolution encompasses significant innovations in automation technology, impacting various industries and reshaping the future of work. Emerging trends and the future of these systems are increasingly intertwined with sophisticated technologies, promising both opportunities and challenges.

Latest Advancements in Automation Technology

Significant advancements in automation technology are driving increased efficiency and productivity. These advancements include improvements in artificial intelligence (AI), machine learning (ML), and robotics. AI and ML algorithms are becoming more sophisticated, enabling machines to perform complex tasks that previously required human intervention. Robotics are evolving to be more versatile, adaptable, and capable of interacting with their environment in increasingly complex ways.

These improvements are leading to more intelligent and responsive automation systems.

Manual vs. automatic car washes often come down to personal preference, but consider this: a quality paint protection film, like the ones available at paint protection film , can significantly reduce the wear and tear on your vehicle’s paint, regardless of whether you choose a manual or automated wash. Ultimately, both methods have their pros and cons, and the right choice depends on individual needs and priorities.

Emerging Trends in Automation

Several emerging trends are shaping the future of automation. These include the increasing integration of automation with the Internet of Things (IoT), the rise of collaborative robots (cobots), and the development of more sophisticated automation software. The integration of IoT sensors and devices into automation systems allows for real-time data collection and analysis, enabling more precise control and optimization of processes.

Cobots are designed to work alongside human workers, enhancing safety and productivity. Sophisticated automation software is improving the design, implementation, and maintenance of automated systems.

Future of Manual and Automatic Systems

The future of both manual and automatic systems is characterized by a blend of these approaches. Manual systems will likely remain relevant in specialized or niche applications where automation is not yet feasible or cost-effective. Automatic systems will continue to evolve, becoming more intelligent, adaptable, and integrated with other technologies. The focus will shift towards human-machine collaboration, leveraging the strengths of both approaches.

Innovative Applications of Automation

Automation is finding innovative applications across various industries. In manufacturing, automated guided vehicles (AGVs) are being used for material handling, increasing efficiency and reducing labor costs. In healthcare, robotic surgery is improving precision and reducing invasiveness. In agriculture, automated harvesting and planting equipment are increasing yields and reducing labor demands. These examples demonstrate the versatility and wide-ranging impact of automation.

Technology Changing the Landscape of Manual and Automatic Processes

Technology is fundamentally altering the nature of manual and automatic processes. Automation is increasing efficiency and productivity, but it also necessitates workforce retraining and adaptation. The changing landscape requires businesses to adapt to the evolving demands of the job market and invest in training and development programs to ensure a smooth transition. This transformation necessitates a proactive approach to workforce development.

Technological Advancements in Automation – Table

| Technology | Description | Impact |

|---|---|---|

| Artificial Intelligence (AI) | Enabling machines to perform complex tasks previously requiring human intervention. | Increased efficiency, automation of complex processes. |

| Machine Learning (ML) | Algorithms enabling machines to learn from data and improve their performance over time. | Enhanced decision-making capabilities, improved predictive maintenance. |

| Robotics | Evolving to be more versatile, adaptable, and capable of interacting with their environment. | Increased precision, automation of repetitive tasks. |

| Internet of Things (IoT) | Integration of sensors and devices into automation systems for real-time data collection and analysis. | Enhanced control, optimization of processes, real-time monitoring. |

| Collaborative Robots (Cobots) | Designed to work alongside human workers, enhancing safety and productivity. | Increased safety, enhanced productivity, human-machine collaboration. |

Case Studies and Examples

Real-world applications offer valuable insights into the effectiveness and limitations of both manual and automatic systems. Analyzing successful implementations and understanding the challenges faced during transitions provides crucial lessons for future endeavors. This section presents concrete examples to illustrate the practical use of each system type.

Manual Systems in Action

Manual systems, relying on human effort, remain prevalent in various sectors. Their application often hinges on tasks requiring flexibility, adaptability, or specialized expertise.

- Construction: Bricklaying, carpentry, and roofing often involve manual labor. The physical dexterity and judgment of skilled workers are essential in these applications. The time taken to complete a task varies based on the worker’s skill level and the complexity of the job.

- Agriculture: Harvesting crops, tending livestock, and planting seeds often depend on manual labor. The reliance on human workers allows for a tailored approach to the specific needs of each farm and crop. This can be crucial for high-value or specialty crops.

- Healthcare: Patient care, medical procedures, and administrative tasks often require a blend of manual and automated systems. The personalized attention provided by manual systems can be essential in certain patient interactions.

Automatic Systems in Action

Automatic systems, powered by technology, are increasingly employed in a variety of applications. These systems often enhance efficiency, reduce errors, and improve safety in high-volume or repetitive tasks.

- Manufacturing: Automated assembly lines in automotive and electronics industries are commonplace. Robots perform repetitive tasks with high precision, leading to increased production rates and reduced labor costs. This process often requires significant upfront investment in machinery.

- Logistics: Automated guided vehicles (AGVs) and robotic sorting systems are used extensively in warehouses and distribution centers. These systems enhance efficiency by automating the movement and sorting of goods. The accuracy and speed of these systems can significantly reduce delivery times and improve inventory management.

- Data Processing: Computer systems automate data entry, analysis, and reporting. This significantly reduces the time required for manual data processing, leading to quicker insights and more informed decision-making. The effectiveness of this system depends on the quality and completeness of the input data.

Comparative Case Studies

The following table summarizes various case studies illustrating the differences between manual and automatic systems.

| Category | Manual System Example | Automatic System Example | Key Differences |

|---|---|---|---|

| Manufacturing | Hand-crafting furniture | Automated woodworking machinery | Manual is flexible, automatic is faster and more consistent. |

| Logistics | Manual sorting of packages in a small business | Automated sorting systems in a large warehouse | Manual is labor-intensive, automatic is efficient for large volumes. |

| Healthcare | Manual patient record keeping | Electronic health records system | Manual is adaptable, automatic offers faster retrieval and analysis. |

Success and Failure in Implementing Automatic Systems

Successful automatic system implementations often involve a phased approach, careful planning, and comprehensive training of the workforce. Failure to address these elements can lead to project delays, budget overruns, and even operational disruptions.

- Success Story: A large retail company successfully implemented an automated inventory management system, reducing stockouts and improving order fulfillment rates. This led to increased customer satisfaction and higher profitability.

- Failure Case: A manufacturing company failed to adequately train its workforce on the new robotic assembly line, leading to significant downtime and operational inefficiencies. This resulted in a project delay and an increase in labor costs. Proper training is crucial for the successful implementation of automation.

Closing Notes

In conclusion, the choice between manual and automatic systems hinges on specific needs and priorities. While manual systems retain a crucial role in certain contexts, automation offers increased efficiency and productivity in many sectors. The detailed analysis presented in this guide highlights the trade-offs and considerations crucial for any organization weighing the benefits of each approach.

Common Queries

What are some common human error factors in manual processes?

Human error in manual processes can stem from fatigue, distractions, lack of training, or misinterpretation of instructions. These errors can lead to decreased accuracy, quality issues, and safety risks.

What are the typical maintenance requirements for automatic systems?

Automatic systems often require scheduled maintenance, including cleaning, lubrication, and component checks. Failure to adhere to maintenance schedules can lead to system malfunctions and decreased lifespan.

How does automation impact employment?

Automation can lead to job displacement in certain roles but also creates new jobs in areas like automation maintenance, programming, and system design. Reskilling and upskilling initiatives are essential to help workers adapt.

What are some examples of industries where manual systems are still prevalent?

Manual systems remain important in industries like artistry, certain aspects of healthcare (e.g., specialized procedures), and niche craftsmanship where human dexterity and judgment are still irreplaceable.