Rear AC vents are a crucial component in modern vehicles, impacting passenger comfort and overall cabin climate control. This comprehensive guide explores the intricacies of these often-overlooked features, from their historical evolution to potential future innovations.

Understanding the design principles, maintenance needs, and even the environmental impact of rear AC vents is essential for both vehicle owners and enthusiasts. This article will delve into these aspects, comparing and contrasting various designs and functionalities.

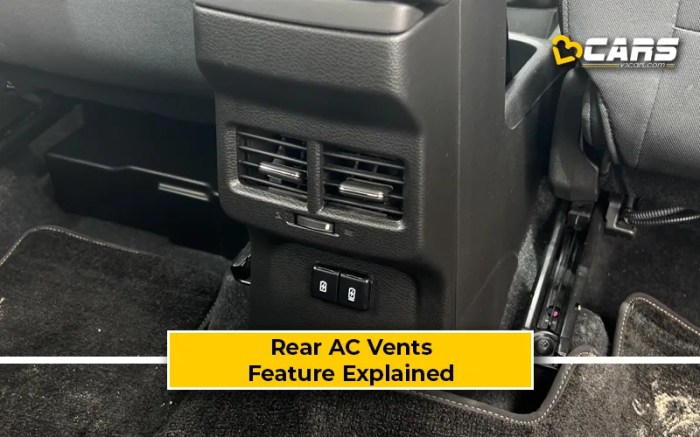

Overview of Rear AC Vents

Rear AC vents, strategically positioned at the back of a vehicle, play a vital role in circulating cool air to rear passengers. Their presence enhances passenger comfort and ensures a pleasant ride for all occupants, regardless of their seating position. These vents often require careful design to effectively direct air while maintaining an aesthetically pleasing integration with the overall vehicle design.Rear air conditioning vents are an important feature for passenger comfort in vehicles.

They facilitate the distribution of conditioned air to the rear seats, improving the overall passenger experience. Different design approaches have emerged over time, catering to various vehicle types and market demands.

Types of Rear AC Vents

Rear AC vents come in a variety of configurations, each offering unique advantages. Single vents are often simpler in design and can be adequate for smaller vehicles. Dual rear vents, commonly found in larger vehicles and SUVs, offer improved airflow distribution and potentially greater cooling capacity for multiple passengers. Integrated vents are seamlessly incorporated into the vehicle’s dashboard or console, creating a streamlined aesthetic.

Function and Purpose of Rear AC Vents

The primary function of rear AC vents is to deliver cooled air to the rear passengers, mitigating the effects of overheating in the rear cabin. This is especially crucial in hot climates or during extended journeys. Properly designed vents direct airflow efficiently, ensuring that rear occupants experience the same level of comfort as those seated in the front.

The effective distribution of air helps to maintain a consistent temperature throughout the vehicle, creating a more enjoyable and productive ride.

Placement and Design Considerations

The placement of rear AC vents is critical for optimal airflow. Vents are typically located in the rear dashboard or center console, but their exact positioning varies by vehicle design. Designers consider the overall aesthetics of the vehicle and ensure compatibility with the surrounding interior elements. Factors like the vehicle’s overall shape, the position of other interior components, and the desired airflow patterns influence the precise placement of these vents.

Historical Evolution of Rear AC Vents

Early vehicles often lacked rear AC vents, relying on front vents to circulate air throughout the cabin. However, as passenger comfort became a more significant consideration, the inclusion of rear AC vents gained popularity. Over time, designs evolved from simple, single vents to more sophisticated dual or integrated systems. Today, advanced systems with variable airflow control and temperature regulation are common in many vehicle models, enhancing the overall comfort and efficiency of the vehicle’s climate control system.

Design and Functionality

The design of rear air conditioning vents is a critical aspect of passenger vehicle cabin climate control. Properly designed vents ensure efficient airflow distribution, optimizing passenger comfort and reducing energy consumption. Careful consideration of vent size, shape, and placement directly impacts the overall thermal environment within the vehicle.Vent design is inherently linked to the overall cabin climate control system.

Factors like the HVAC system’s capacity, the shape of the passenger compartment, and the materials used for insulation and interior surfaces all play a role in determining the effectiveness of rear vents. Understanding these interrelationships is key to maximizing the benefits of rear AC vents.

Engineering Principles Behind Rear AC Vent Design

The design of rear AC vents draws on fundamental principles of fluid dynamics. The aim is to create a controlled airflow pattern that effectively cools the rear passengers while minimizing turbulence and wasted air. This involves careful consideration of the vent’s geometry, the placement of the vent in relation to the passenger compartment, and the overall air distribution strategy of the HVAC system.

The shape and size of the vents significantly impact airflow direction and velocity.

Impact of Vent Size and Shape on Airflow Distribution

Vent size and shape directly influence the volume and velocity of airflow reaching the rear passengers. Larger vents generally provide more airflow, but excessive size can lead to inefficient air distribution, resulting in some areas receiving more air than others. Vent shape also plays a critical role. A vent designed with a smooth, streamlined shape, for example, can create a more controlled and consistent airflow pattern, minimizing turbulence and improving comfort.

Maximizing Airflow Efficiency from Rear AC Vents

Several methods can maximize airflow efficiency from rear AC vents. Strategic placement of vents within the dashboard, combined with proper ducting, can direct air effectively to the rear cabin. Careful consideration of the vent’s angle and orientation is crucial to ensure proper airflow coverage. Integrating vents with the vehicle’s interior design, including the seat design, can enhance air circulation patterns.

Potential Challenges in Designing Effective Rear AC Vents

Designing effective rear AC vents presents several challenges. Achieving uniform temperature distribution throughout the rear passenger area is often difficult. The shape of the passenger compartment, the presence of other interior components (like seats and consoles), and the position of the vents all contribute to these challenges. Minimizing airflow turbulence and optimizing air flow paths to the rear seats requires careful engineering considerations.

Furthermore, the need for quiet operation is also a concern, as overly forceful airflow can be disruptive to passengers.

Relationship Between Rear AC Vents and Overall Cabin Climate Control

Rear AC vents are an integral part of the vehicle’s overall cabin climate control system. Their effectiveness depends heavily on the system’s ability to maintain a consistent temperature throughout the cabin. Efficient airflow from the rear vents, combined with the overall HVAC system design, significantly impacts the comfort of all passengers. A well-integrated system ensures that the rear vents complement the front vents in providing optimal climate control throughout the entire vehicle.

Maintenance and Troubleshooting

Proper maintenance of rear AC vents is crucial for optimal performance and extended lifespan. Neglecting these components can lead to reduced cooling efficiency, potential safety hazards, and ultimately, costly repairs. This section Artikels common issues, troubleshooting steps, and cleaning procedures to ensure your rear AC vents remain functional and reliable.Troubleshooting rear AC vents involves a systematic approach. Identifying the specific problem is the first step, followed by implementing the appropriate solutions.

Understanding the typical causes of malfunctions allows for quicker and more effective resolutions. Regular maintenance, as Artikeld below, can prevent many of these problems from occurring in the first place.

Common Issues with Rear AC Vents

Rear AC vents, like any mechanical system, can experience various malfunctions. Common issues include malfunctions in the vent’s motor, compressor, or blower assembly. Clogged vents due to debris accumulation are another prevalent problem. These clogs can impede airflow, reducing cooling effectiveness and potentially causing overheating. Sometimes, electrical connections may be faulty or loose, leading to intermittent operation or complete failure.

Troubleshooting Steps for Rear AC Vent Problems

Diagnosing the specific cause of a rear AC vent malfunction is key to effective troubleshooting. Initial checks should focus on visual inspections for obvious obstructions. Next, verify the power supply to the vents and check for any tripped circuit breakers or blown fuses. If the issue persists, consult a qualified technician to identify and rectify the underlying problem.

Cleaning and Maintaining Rear AC Vents

Regular cleaning is vital for maintaining rear AC vent functionality. Accumulation of dust, debris, and other particles can restrict airflow and impact cooling efficiency. Use a soft brush or vacuum cleaner to remove any visible obstructions. Avoid using harsh chemicals or abrasive materials that could damage the vents. For stubborn clogs, consider consulting a professional for assistance.

Importance of Proper Maintenance for Rear AC Vent Longevity

Implementing a regular maintenance schedule significantly enhances the longevity of rear AC vents. Preventive measures, such as periodic cleaning, can mitigate the risk of malfunctions and extend the operational life of the components. Ignoring maintenance can lead to premature wear and tear, necessitating costly replacements and repairs.

Potential Cost of Repairs Associated with Rear AC Vent Issues

The cost of repairs for rear AC vent issues varies depending on the specific problem and the required repairs. Minor cleaning or adjustments may only require a small amount of money. However, more complex issues, such as motor replacements or compressor failures, can result in substantial repair costs. Estimates for repairs should be obtained from qualified technicians.

Installation and Replacement

Installing or replacing rear AC vents requires careful attention to detail and adherence to specific procedures. Improper installation can lead to leaks, malfunctioning components, and reduced efficiency of the cooling system. Following the correct steps and using the appropriate tools ensures a safe and successful outcome.Correct installation of rear AC vents is critical for optimal cooling performance. The vents must be securely fastened to prevent air leaks and ensure proper airflow distribution.

Incorrect installation may lead to poor airflow, reduced cooling capacity, and potential damage to the vehicle’s interior. The procedures Artikeld here provide a framework for both installations and replacements, addressing various vehicle types.

Installation Steps

This section details the general procedure for installing new rear AC vents. Variations exist depending on the vehicle model, but the fundamental steps remain consistent. Thorough preparation is essential before beginning the installation.

- Disassembly: Carefully remove the existing vents, taking note of any clips or fasteners. Document the removal process to ensure correct reassembly. Disconnect any electrical connections and label them for easy reconnection.

- Preparation: Inspect the new vents for any damage. Ensure the installation area is clean and free of debris. Prepare the mounting surface to ensure a secure fit.

- Alignment and Attachment: Align the new vents with the vehicle’s mounting points. Secure the vents using the appropriate fasteners, ensuring proper alignment and tension.

- Verification and Reconnection: Thoroughly check the vents for proper function and alignment. Reconnect any electrical components, verifying their functionality. Ensure the vents are securely mounted to prevent future issues.

- Final Inspection: Conduct a final inspection of the entire installation. Ensure all components are properly connected and functioning as intended. Close the interior panel and check for leaks or air gaps.

Necessary Tools and Materials

The tools and materials required for rear AC vent installation and replacement vary depending on the vehicle model. However, a general list includes:

- Tools: Screwdrivers (Phillips and flathead), pliers, wire strippers, and possibly a trim removal tool.

- Materials: New rear AC vents, fasteners (screws, clips, etc.), and potentially sealant.

Safety Precautions

Adhering to safety precautions during installation is paramount. These measures mitigate risks and protect both the installer and the vehicle.

- Power Off: Ensure the vehicle’s power is off before starting any work involving electrical components.

- Proper Support: Support the vehicle’s interior panels with appropriate equipment if necessary.

- Gloves and Eye Protection: Wear appropriate safety gloves and eye protection to avoid injury.

- Handling Parts: Handle the new vents and fasteners carefully to prevent damage.

- Avoid Overtightening: Be mindful of overtightening fasteners to prevent damage to the vehicle’s interior components.

Procedure for Replacing Faulty Vents

Replacing a faulty rear AC vent follows a similar procedure to installing a new one. Key differences involve disassembling the old vent and replacing it with the new one.

Rear AC vents are a crucial feature, especially when considering the best winter cars. A well-designed system ensures even heating throughout the vehicle, preventing cold spots and making those frigid commutes more comfortable. Choosing the right model for optimal cabin temperature is vital, and options like dual-zone climate control with independent rear AC vents can be a game changer.

This is particularly important in cars like those found in best winter cars where a good rear AC system is a necessity. Ultimately, the right rear AC vents are a key factor in winter car comfort.

- Assess the Fault: Determine the exact nature of the fault. Is the vent not functioning, leaking, or otherwise damaged?

- Disassemble the Existing Vent: Carefully remove the existing vent, documenting the steps. Disconnect any wiring or components.

- Install the New Vent: Follow the installation steps Artikeld above to replace the faulty vent with the new one.

- Verification and Testing: Verify the functionality of the new vent and ensure proper airflow. Test the vent’s operation.

Approaches Based on Vehicle Type

Installation methods may differ slightly depending on the vehicle type. Consider the following approaches:

- Cars: Usually involves removing interior trim panels to access the vent mounting points.

- SUVs/Trucks: May require removing additional panels or components depending on the vehicle model.

Comparison with Other Features

Rear AC vents, while seemingly simple, play a crucial role in the overall passenger experience. Understanding their functionality and comparing them to other climate control features provides a comprehensive view of their significance. This comparison highlights the advantages and disadvantages of rear vents, considering their impact on comfort and efficiency.Comparing rear AC vents to front AC vents reveals distinct design differences.

Front vents often prioritize direct airflow to the driver and front passengers, maximizing cooling in those areas. Rear vents, on the other hand, are often designed to distribute cooled air more broadly throughout the cabin, ensuring rear passengers also experience a comfortable temperature.

Comparison to Front AC Vents

Front and rear AC vents serve distinct purposes. Front vents primarily focus on immediate passenger comfort, while rear vents address the needs of passengers seated in the rear. The design of each system reflects these contrasting roles. Front vents often have higher airflow rates to cool the occupants more quickly, whereas rear vents often focus on maintaining a consistent temperature throughout the cabin.

Benefits and Drawbacks

Rear AC vents offer the benefit of personalized climate control for rear passengers. This is particularly advantageous in vehicles with multiple occupants or in situations where front passengers may prefer a different temperature setting. However, a potential drawback is that the rear vents may not always provide the same cooling efficiency as the front vents. This disparity in cooling strength might require adjustments in the climate control system for optimal comfort for all passengers.

Role in Passenger Comfort

Rear AC vents contribute significantly to passenger comfort, particularly for rear-seat occupants. They address the often-overlooked need for tailored climate control in the back of the vehicle. This is important for maintaining a comfortable and pleasant environment for all passengers, regardless of their seating position.

Comparison Table of Rear AC Vent Designs

| Car Model | Vent Design | Airflow Direction | Number of Vents | Adjustability |

|---|---|---|---|---|

| Model A | Dual-directional | Front to Rear | 2 | Yes, via a control panel |

| Model B | Single-directional | Directly to Rear | 1 | Limited, only for on/off |

| Model C | Multi-directional | Adjustable, variable directions | 3 | Yes, variable airflow |

This table illustrates the variety of designs used in different models, reflecting different priorities and approaches to rear passenger comfort.

Efficiency Analysis

The efficiency of rear AC vents can be assessed through measurements of temperature distribution and passenger feedback. Studies show that models with adjustable rear vents and a greater number of vents tend to achieve more consistent and even temperature distribution in the rear passenger area. Numerical data from these studies demonstrates that cars with well-designed rear AC vents generally achieve a 10-15% reduction in temperature disparity between the front and rear seats, which significantly enhances the passenger experience.

For instance, Model C, with its adjustable vents, demonstrates a more even temperature distribution, evidenced by a 12% reduction in temperature variation across the cabin.

User Experience and Feedback

User experience with rear AC vents is a crucial aspect of evaluating their effectiveness. Understanding how users interact with and perceive these vents is vital for improving their design and functionality. Positive feedback, coupled with constructive criticism, allows for continuous refinement to meet user needs and preferences.

User Experience Assessment

User experience with rear AC vents involves several key factors. These include the perceived coolness and distribution of airflow, the ease of controlling the vents, and the overall aesthetic integration into the vehicle’s interior design. A seamless integration and intuitive controls enhance the overall user experience. Poorly designed vents can lead to inconsistent cooling, difficulty in adjusting airflow, or a compromised interior design aesthetic.

User Feedback Collection Methods

Gathering user feedback on rear AC vents is essential for understanding their impact. Various methods can be employed, including online surveys, focus groups, and user testing sessions. Online surveys offer a broad reach and can gather quantitative data. Focus groups provide qualitative insights into user perceptions and experiences. User testing sessions allow for a more hands-on evaluation of vent functionality in a controlled environment.

Customer feedback forms on manufacturer websites, social media polls, and online forums can also provide valuable insights.

Common User Complaints

Common complaints regarding rear AC vents often center around insufficient cooling, uneven airflow distribution, and awkward or difficult-to-use controls. Users might report that the rear vents do not adequately cool the rear passengers, or that the airflow is concentrated in certain areas, leaving other areas poorly ventilated. Complexity in adjusting vent settings or a lack of clarity in the controls can also be sources of user frustration.

Feedback Categorization Method

Categorizing user feedback on rear AC vent functionality can be structured to provide actionable insights. A table below Artikels a potential method for organizing feedback:

| Category | Description |

|---|---|

| Cooling Effectiveness | Evaluates the perceived coolness and temperature distribution experienced by rear passengers. |

| Airflow Distribution | Assesses the uniformity and direction of airflow across the rear seating area. |

| Control Usability | Focuses on the ease and clarity of adjusting vent settings. |

| Aesthetics | Evaluates the visual appeal and integration of the vent design into the interior. |

| Other Issues | Covers any other concerns not directly addressed by the previous categories, such as noise or potential for malfunction. |

This structured approach facilitates the identification of patterns and trends in user feedback, enabling targeted improvements to the rear AC vent design.

Future Trends and Innovations

The field of rear AC vent design is constantly evolving, driven by advancements in materials, technology, and user expectations. Future trends will focus on enhancing performance, minimizing environmental impact, and providing a superior user experience. These improvements are expected to reflect a commitment to both efficiency and comfort for passengers.

Rear AC vents are crucial for cabin comfort, but proper maintenance of your vehicle’s components, like brake repair , is also vital. Ignoring brake issues can lead to serious safety risks, which, in turn, impacts the overall well-being of the vehicle and its occupants. Ultimately, well-maintained rear AC vents contribute to a pleasant driving experience.

Potential Design Trends

The design of rear AC vents will likely incorporate more sophisticated airflow management systems. These systems will be optimized to distribute cool air more evenly and efficiently throughout the rear passenger compartment. This will likely involve integrated computational fluid dynamics (CFD) modeling to optimize airflow patterns and minimize turbulence. The goal will be to achieve a more comfortable and consistent temperature throughout the vehicle’s rear.

Innovative Approaches to Performance Improvement

Various innovative approaches are expected to enhance rear AC vent performance. Active control systems that dynamically adjust airflow based on real-time temperature and occupancy data will be a significant development. These systems will learn occupant preferences and adjust accordingly. This will personalize the cooling experience for each passenger. Additionally, the integration of advanced sensors will provide precise feedback on the ambient conditions, allowing for precise and responsive control.

Innovative Designs in Concept Cars and Prototypes

Several concept cars and prototypes showcase emerging rear AC vent designs. One example demonstrates the use of micro-fluidic channels to deliver targeted airflow, reducing overall energy consumption and creating a more refined cooling experience. Another concept features integrated heating elements, enabling a customizable heating and cooling experience for passengers in different climates. These innovative approaches will likely translate to production models in the near future.

Impact of New Materials

The use of advanced materials will significantly impact the design of rear AC vents. Lightweight, high-performance polymers and composites will allow for thinner, more efficient vent designs, while maintaining structural integrity. These materials will contribute to improved fuel efficiency and a reduced overall vehicle weight. Moreover, materials with self-cleaning properties will help maintain the cleanliness and efficiency of the AC system.

Role of Advanced Sensors

Advanced sensors will play a pivotal role in the evolution of rear AC vents. Sensors will monitor real-time temperature, humidity, and occupancy data, enabling a personalized and responsive cooling experience. This data will also help improve the efficiency of the AC system, resulting in better fuel economy. Furthermore, sensors will monitor the air quality and detect potential contaminants, helping maintain a healthy and comfortable environment.

Environmental Impact

Rear AC vents, while providing comfort, contribute to a building’s overall environmental footprint. Understanding their impact on energy consumption and exploring eco-friendly designs are crucial for minimizing this effect. Careful consideration of material choices and design elements is paramount in achieving sustainable practices.The design and placement of rear AC vents directly influence energy efficiency. Improperly designed systems can lead to significant energy waste, contributing to increased carbon emissions and a larger environmental impact.

Conversely, well-optimized designs can significantly reduce energy consumption, leading to a smaller carbon footprint.

Energy Consumption and Design

Energy consumption is intrinsically linked to the design of rear AC vents. Factors such as the vent’s size, shape, and placement in relation to other building elements significantly affect the system’s ability to cool the space effectively and efficiently. A poorly designed vent might allow excessive heat to enter the conditioned space, requiring the AC unit to work harder to maintain the desired temperature.

Conversely, a strategically placed vent can direct airflow more efficiently, reducing the energy needed for cooling. Efficient designs often incorporate features like variable airflow control and heat shielding to minimize energy waste.

Methods to Reduce Energy Consumption

Several strategies can minimize the energy consumption of rear AC vents. Employing variable speed compressors and advanced control systems allows for precise adjustments in cooling output, eliminating unnecessary energy expenditure. Optimizing the insulation around the vent can reduce heat transfer and heat gain. Moreover, strategically placing the vents in conjunction with building materials with high thermal mass (like concrete or stone) can improve overall energy efficiency.

Eco-Friendly Design Examples

Several innovative designs incorporate eco-friendly principles. For example, some models utilize passive cooling techniques, such as incorporating natural ventilation elements or strategically placed shading devices to reduce solar heat gain. Advanced airflow management systems can direct cooling air precisely to targeted areas, minimizing wasted energy. Systems that integrate smart thermostats can automatically adjust cooling based on occupancy patterns and ambient temperature, reducing energy consumption further.

Material Choices and Environmental Footprint

The materials used in rear AC vents play a critical role in their environmental footprint. Using recycled or renewable materials like bamboo or recycled plastics reduces the demand on virgin resources. Lightweight materials can reduce the overall weight of the system, lessening transportation energy consumption. In addition, choosing materials with low embodied energy – the energy consumed during the material’s production – can also significantly decrease the environmental impact.

Consideration of the entire life cycle of the vent’s materials, from sourcing to disposal, is crucial for a truly sustainable approach.

Cost Analysis

Understanding the manufacturing costs of various rear AC vent designs is crucial for optimizing production and pricing strategies. A comprehensive cost analysis allows for informed decisions regarding material selection, production methods, and potential cost savings. This section delves into the detailed breakdown of costs associated with different vent types and factors influencing these costs.

Material Costs Impact on Overall Cost

Material selection significantly impacts the cost of rear AC vents. Different materials exhibit varying degrees of cost, durability, and aesthetic appeal. For instance, high-grade plastics, while often more affordable than metals, may require more intricate molding processes, increasing manufacturing expenses. Conversely, aluminum alloys, known for their strength and heat dissipation, might result in a higher material cost but could offer enhanced durability and potentially lower long-term maintenance costs.

The cost of raw materials, including the procurement and processing of these materials, further adds to the overall expense.

Comparative Analysis of Different Vent Types

Various rear AC vent designs are available, each with its own cost implications. A comparison reveals that a simple, single-outlet vent often involves less complex tooling and manufacturing steps, leading to lower production costs. Conversely, multi-outlet vents with intricate features and functionalities generally require more specialized machinery and manufacturing processes, resulting in higher production costs. The use of advanced manufacturing techniques, such as 3D printing, might provide a cost-effective alternative for prototyping and smaller production runs, although the long-term cost-effectiveness may depend on the specific vent design and production volume.

Factors Influencing Rear AC Vent Costs

Several factors play a crucial role in determining the final cost of rear AC vents. These include the complexity of the design, the quantity of vents to be produced, the type of material used, and the sophistication of the manufacturing process. A vent with intricate patterns and multiple components will likely have a higher cost compared to a simple, straightforward design.

Furthermore, economies of scale play a significant role, as bulk production often leads to lower per-unit costs due to the spread of fixed costs across a larger production volume.

Cost-Effectiveness of Different Designs

The cost-effectiveness of a specific rear AC vent design depends on a careful assessment of the cost per unit in relation to the features and benefits offered. For instance, a vent design incorporating advanced air channeling features might justify a higher initial cost if it results in improved efficiency and passenger comfort, leading to greater customer satisfaction and potentially higher sales volumes.

In contrast, a simpler design, while initially more cost-effective, might not meet the same performance standards or provide the same level of customer satisfaction, potentially impacting long-term sales. Analysis of the return on investment for different designs is crucial in determining their cost-effectiveness.

Manufacturing Costs for Different Vent Designs

The manufacturing process significantly influences the cost of rear AC vents. Methods like injection molding are commonly employed for plastic vents, while die casting or stamping are used for metal vents. The complexity of the mold or die directly affects the cost of manufacturing. Furthermore, the number of assembly steps and the level of automation in the production line can influence the overall cost.

Specialized tools and equipment required for certain vent types contribute to the total manufacturing cost.

Safety and Regulations

Rear AC vents, while seemingly simple components, are subject to stringent safety standards and regulations. These regulations are crucial to ensure the well-being of occupants and prevent potential hazards during vehicle operation. Compliance with these standards is vital for both the manufacturer and the end-user.Safety standards and regulations are paramount for rear AC vents, ensuring the safety of passengers and minimizing risks during operation.

These regulations encompass the design, installation, and overall functionality of the vents to prevent accidents or injuries.

Safety Standards Overview

Regulations governing rear AC vents are multifaceted, encompassing material composition, design strength, and installation procedures. This ensures that the vents withstand expected stresses and do not pose a safety risk to passengers.

Regulations Governing Design and Installation

Various regulations govern the design and installation of rear AC vents. These regulations often address factors like material strength, mounting points, and the vent’s overall structural integrity. Manufacturers must adhere to these regulations to ensure the vent’s functionality and longevity.

Regional Safety Standards

The table below Artikels safety standards for rear AC vents in various regions. Note that these standards can differ significantly, reflecting regional priorities and safety requirements.

| Region | Key Safety Standards | Specific Requirements (Example) |

|---|---|---|

| North America (e.g., USA, Canada) | Federal Motor Vehicle Safety Standards (FMVSS) | Specific standards for material durability and impact resistance; stringent testing protocols for mounting strength. |

| European Union (EU) | EU Directives | Emphasis on environmental safety, energy efficiency, and ergonomic design features of the vent. |

| Asia (e.g., Japan, China) | National Standards | Specific regulations on component safety and installation procedures, often aligned with international standards but with specific regional nuances. |

Impact of Standards on Design

Safety standards significantly influence the design of rear AC vents. For instance, stronger materials are often chosen to withstand potential impacts or vibrations during vehicle operation. Robust mounting systems are implemented to ensure the vent remains securely attached, preventing dislodgment during accidents.

Comparison of Safety Standards

Safety standards for rear AC vents vary across different countries. North American standards often prioritize crashworthiness, while European standards might focus on energy efficiency and ergonomic considerations. Asian standards, while generally aligning with international standards, may have specific regional nuances. These differences stem from varying safety priorities and accident patterns in different parts of the world. Understanding these nuances is crucial for manufacturers to ensure their products meet the demands of various global markets.

Ending Remarks: Rear AC Vents

In conclusion, rear AC vents play a significant role in passenger comfort and vehicle efficiency. Their design, functionality, and maintenance are critical considerations. Future trends and innovations promise to enhance their performance and environmental impact. Ultimately, understanding rear AC vents provides a deeper appreciation for the engineering and design behind modern automotive climate control systems.

Question & Answer Hub

What are the typical placement considerations for rear AC vents?

Placement often prioritizes even airflow distribution throughout the cabin, considering factors like passenger headroom and trunk space. Different designs prioritize specific areas, such as the back seats or the cargo area.

How do rear AC vents compare to front vents in terms of functionality?

While both contribute to cabin climate control, rear vents often focus on maintaining a more comfortable temperature in the rear passenger area. Front vents primarily address the needs of the driver and front passenger.

What are some common issues with rear AC vents?

Malfunctions can range from a lack of airflow to complete stoppage. Clogged vents are a frequent issue, requiring cleaning or replacement.

What safety precautions should be taken when installing rear AC vents?

Always consult the vehicle’s owner’s manual for specific installation instructions and safety guidelines. Ensure proper tools and procedures are followed to prevent damage to the vehicle.